機台設備與部件(Equipment and Parts)

-

Read More

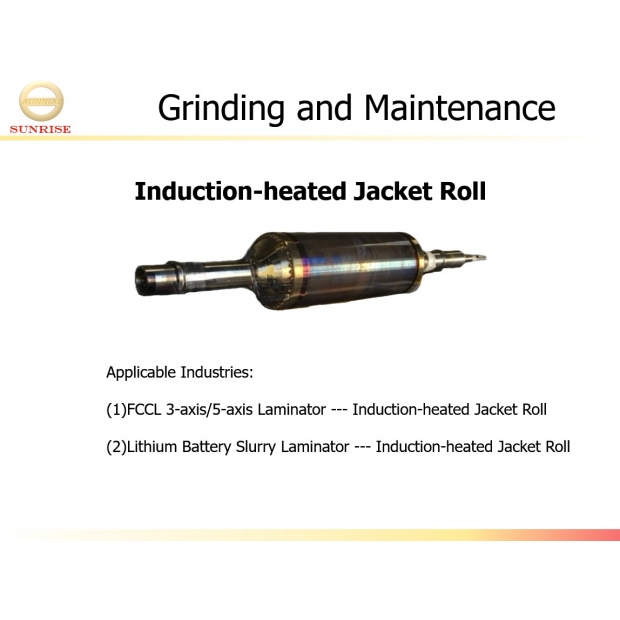

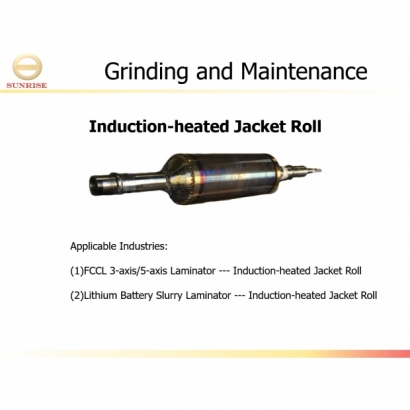

Induction-heated Jacket Roll --- Grinding and Maintenance(熱壓合輪研磨修整)

Induction-heated Jacket Roll --- Grinding and Maintenance(熱壓合輪研磨修整)Induction-heated Jacket Roll --- Grinding and Maintenance(熱壓合輪研磨修整)

Induction-heated Jacket Roll --- Grinding and Maintenance(熱壓合輪研磨修整)

Applicable Industries:

(1)FCCL 3-axis/5-axis Laminator --- Induction-heated Jacket Roll

(2)Lithium Battery Slurry Laminator --- Induction-heated Jacket Roll -

Read More

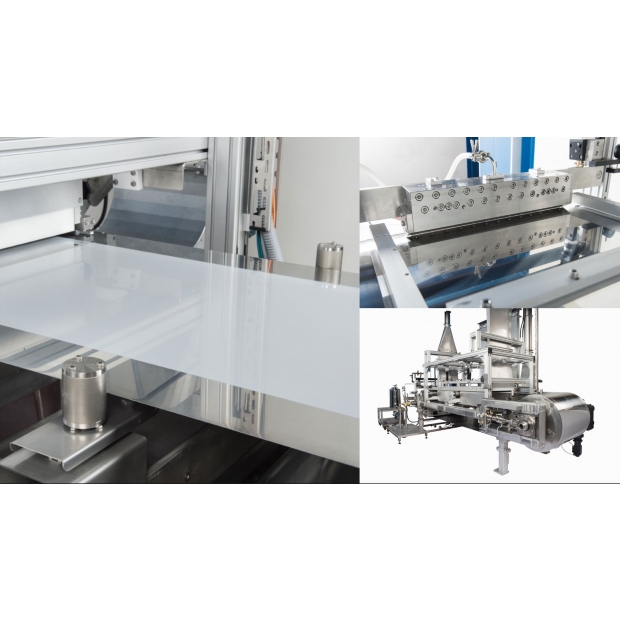

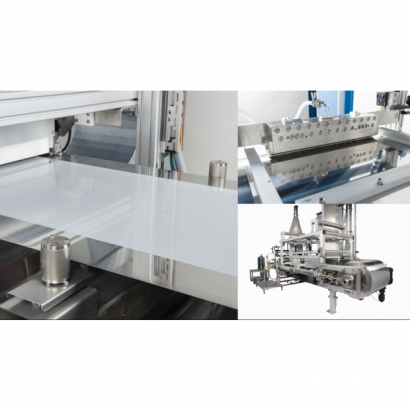

連續式塗布機台和文丘里乾燥系統(Continuous Film Casting Machine and Venturi Drying System)

連續式塗布機台和文丘里乾燥系統(Continuous Film Casting Machine and Venturi Drying System)連續式塗布機台和文丘里乾燥系統(Continuous Film Casting Machine and Venturi Drying System)

Ongoing investment in R&D, coupled with our proven experience and expertise in process technologies for the production of film materials, has resulted in the successful development of an innovative Venturi drying system for film casting applications.

The production line begins with a slot die that applies an accurately controlled layer of liquid product onto a polished steel belt.

From here it passes through the Venturi dryer where the solvent – aqueous or organic – is evaporated quickly, efficiently and in a manner that leaves the end product almost completely free of tension both laterally and longitudinally.

This high precision system dramatically improves the casting process, enabling the production of film products to exceptionally narrow tolerances without any risk of skin formation, and eliminating costly faults and imperfections in the final material.

The inherent benefits of this indirect drying solution also result in a high degree of energy efficiency.

While the IPCO film casting system offers a number of unique market benefits, the compact Venturi dryer can also be used in conjunction with other drying technologies including traditional impingement dryers.

Excellent thermal and air flow effects.

The key benefits of the IPCO Venturi dryer are achieved through the use of a permeable metal foam above the drying film.

A flow of tempered air is applied to the upper side of this foamlike metallic material, creating a low negative pressure effect on the lower side in accordance with the standard laws of pneumatics.

As a result, a constant and even suction flow is formed, delivering a homogeneous drying effect.

This minimizes thermally-induced shrinkage and eliminates the risk of structural defects in the surface and layer structure of the film. -

Read More

皮秒雷射設備與代工(Picosecond Laser Equipment and OEM)

皮秒雷射設備與代工(Picosecond Laser Equipment and OEM)皮秒雷射設備與代工(Picosecond Laser Equipment and OEM)

東鋅 <<皮秒雷射設備與代工>>

(Tung Hsin Picosecond Laser Equipment and OEM)

(A)高精密皮秒切割機:

應用範圍Application Range:

本機主要用於PI/MPI膜、LCP、覆蓋膜、FPC柔性線路板、COP膜等材料的高品

質鐳射切割、刻槽、開窗。在3C、醫療、汽車等領域有廣泛的應用。

This machine is mainly used for high-quality laser cutting, engraving, and window opening of PI/MPI film, LCP, cover film, FPC flexible circuit board, COP film, and other materials. It has a wide range of applications in 3C, medical, automotive, and other fields.

(B)皮秒雷射消融切割機:

應用範圍Application Range:

設備特點Equipment Feature:

本機主要用於陶瓷\藍寶石\玻璃產品的等透明脆性材料的鐳射消融切割,可廣泛應用於

3C領域指紋模組/攝像頭模組保護蓋等0.5mm厚度以下產品的高速高質切割與開槽應用。

This machine is mainly used for laser ablation cutting of transparent brittle materials such as glass/sapphire/ceramic products.

It can be widely used in high-speed high-quality cutting and slotting of products with a thickness of 0.5mm or less in a 3C field fingerprint module/camera module protection cover. -

Read More

IPCO 鋼帶 & DBP鋼帶壓合機

IPCO 鋼帶 & DBP鋼帶壓合機IPCO 鋼帶 & DBP鋼帶壓合機

IPCO Steel Belt & DBP Steel Belt Laminator:

(A) Steel Belt:

Super Mirror Polished Steel Belt Applications: Optical film, PI film, FCCL 2-Layer, etc.

Suitable for FCCL 2-Layer production, with excellent steel strip quality and craftsmanship, ensuring long-term FCCL product production quality.

(B) DBP steel belt pressing machine:

Isochoric = Gap controlled isovolumetric pressing