Customer groups: Avary Holding, Flexium Interconnect (Kunshan), AAC, NETRON, Career, Uniflex Technology (Jiangsu), Uniflex, Dayinmao, AKM Meadville, etc.

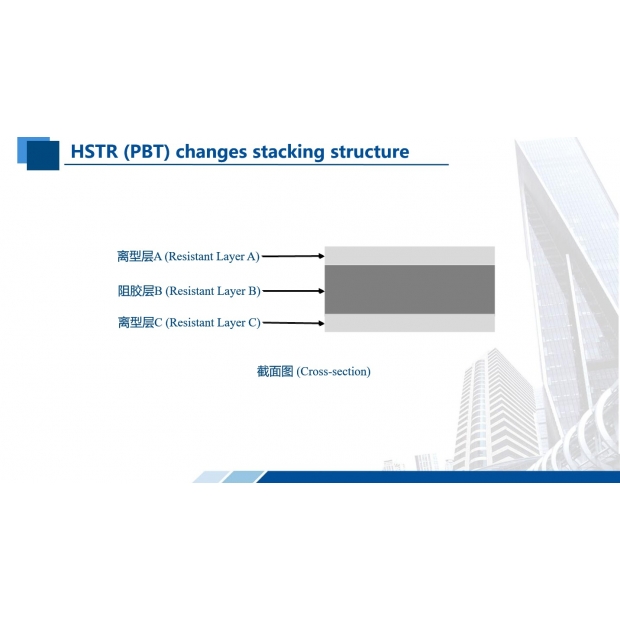

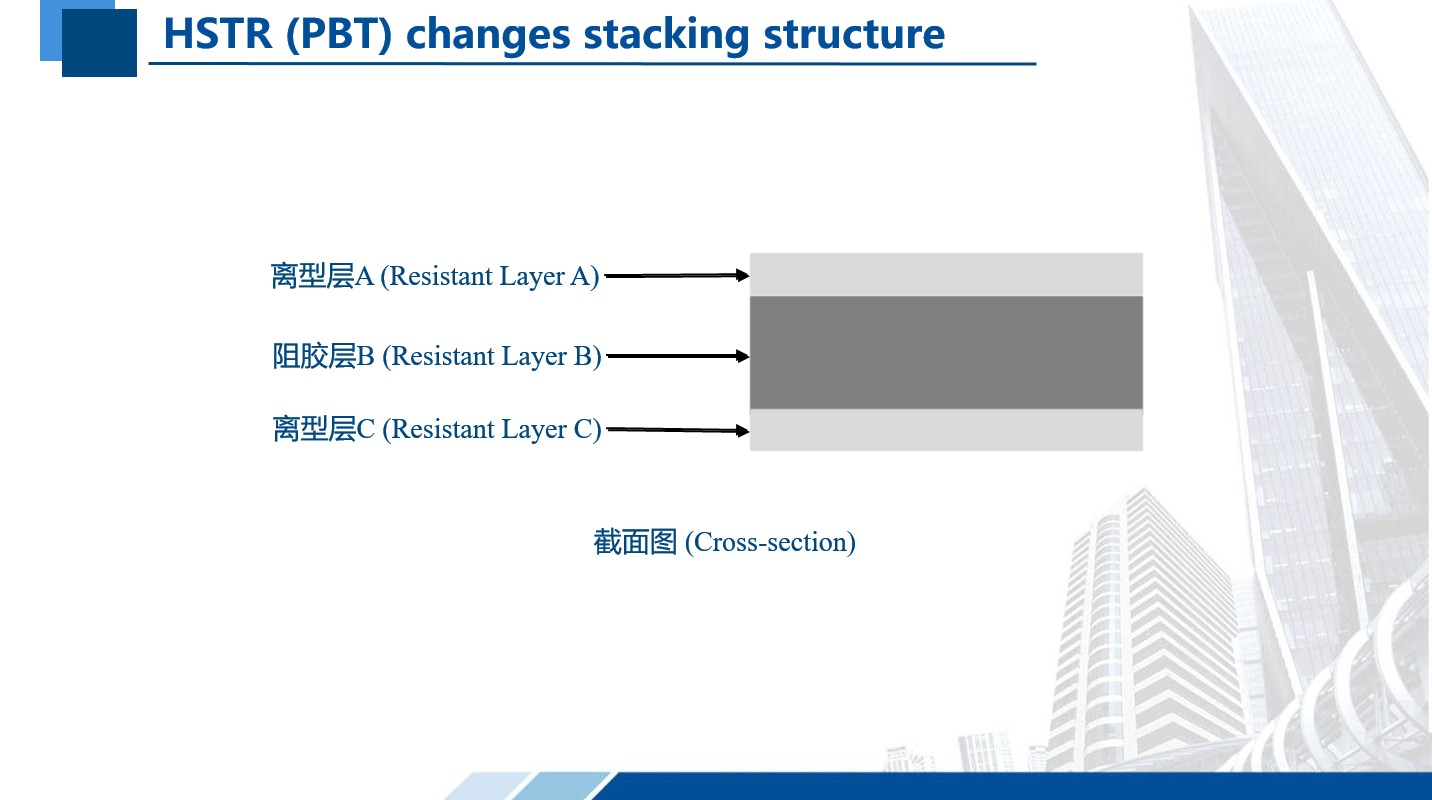

HSTR (PBT) is a three-layer co-extrusion technology with high R&D difficulty, high cost, stable quality, and no silicone oil.

The performance is close to TPX.

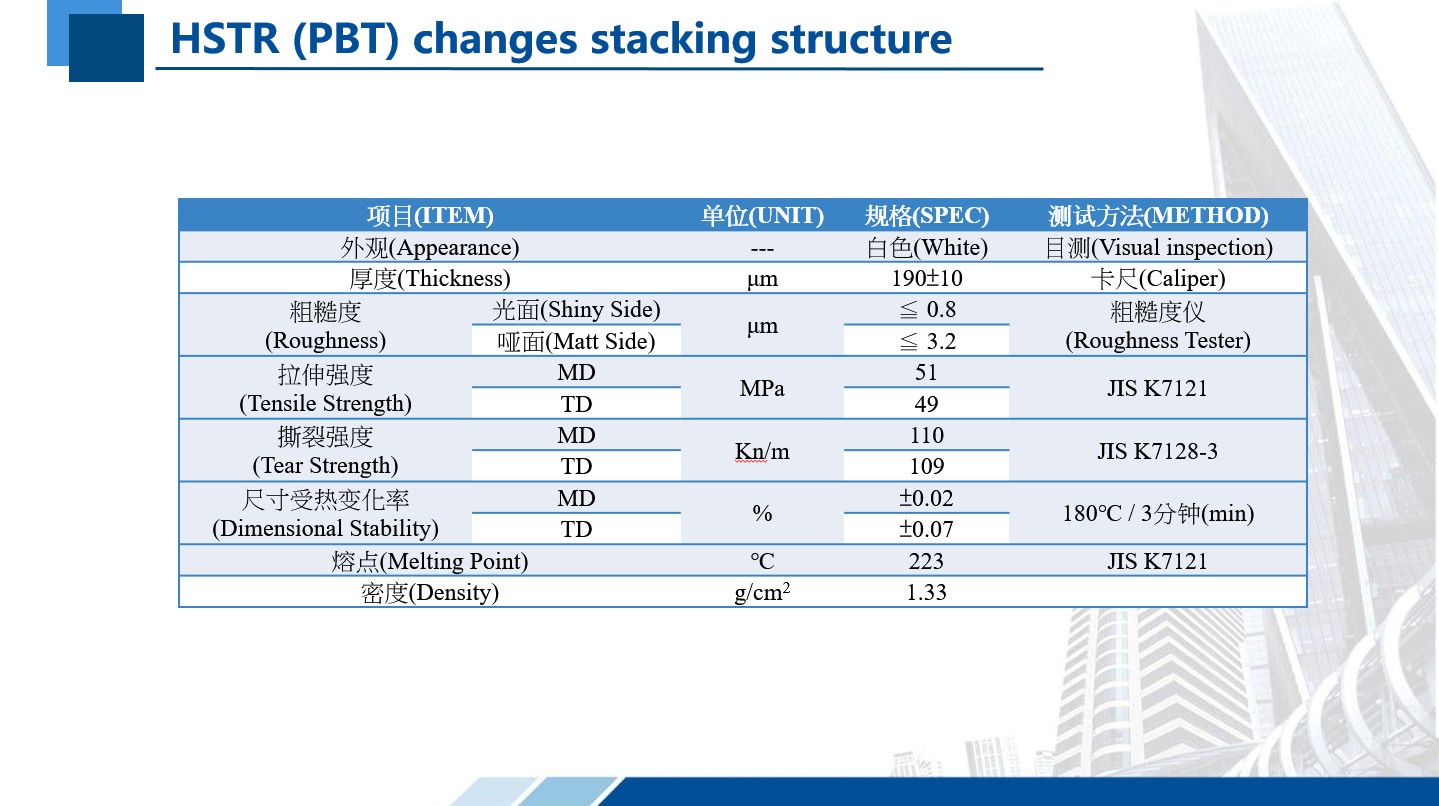

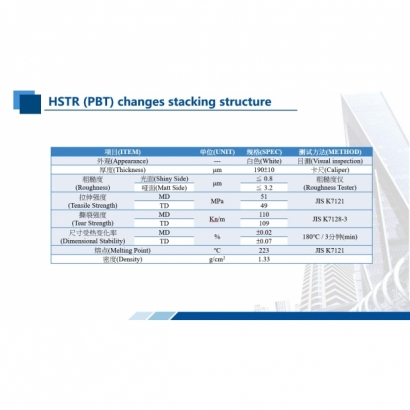

HSTR-190 series release film technical parameters

1. Product features

This product is suitable for use in high-speed laminating operations on FPC boards.

After laminating, the board surface is flat, wrinkle-free, with no residual glue and no pollution.

After laminating, it is easy to peel off, and the CVL glue has a good flow effect.

2. Materials and results

This product is made of special high-temperature resistant poly 4-methylpentene-1 monomer copolymer, polybutylene terephthalate, and other materials for casting.

It has good heat resistance, low shrinkage, and good use effect.

It meets ROHS requirements and is a green product; it does not contain Silicone and will not cause reliability problems to the product.

3. Product characteristics

Appearance-white (visual inspection)

Thickness-190um±10um (vernier caliper)

Roughness - Smooth surface S/S ≦0.8um, matte surface M/S ≦3.2um (roughness meter)

Tensile strength - MD 51MPa, TD 49 MPa (JIS K7127)

Tear strength - MD 110Kn/m, TD 109Kn/m (JIS K7128-3)

Dimensional thermal change rate - MD ±0.02, TD ±0.07 (180°C, 3 minutes)

Melting point - 223℃ (JIS K7121)

Density - 1.33g/cm²

4. Recommended laminating parameters

High speed lamination 180±10℃, pressure 120±40KG/CM², preheating 0-15 seconds, molding 100-360 seconds

Vacuum machine 180±10℃, pressure 20±5KG/CM², Preheating 0-15 seconds, molding 100-360 seconds

5. Storage conditions

Optimal storage conditions: 5-30℃

Avoid direct sunlight, low temperature (below 0℃), high temperature (above 40℃), high humidity (above 70%RH)

Storage period: 12 months from the date of production