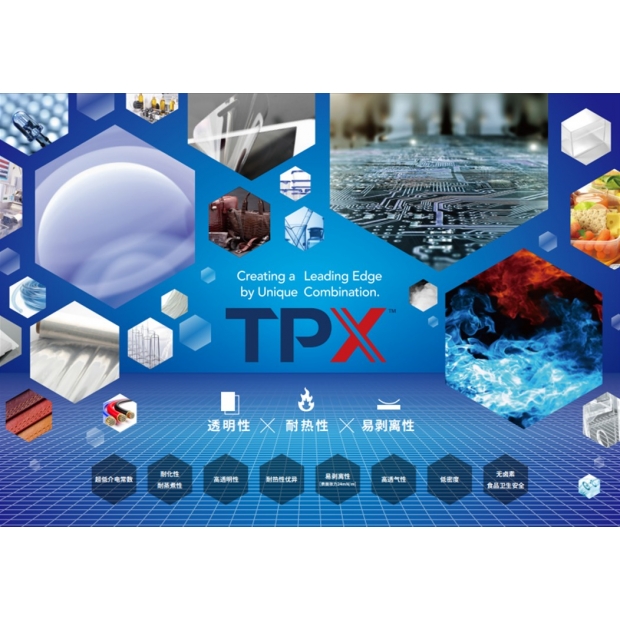

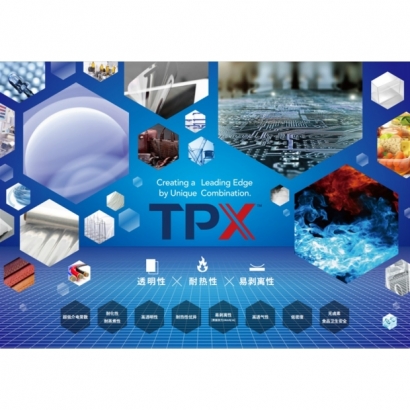

TPX™ (Polymethyl Pentene)

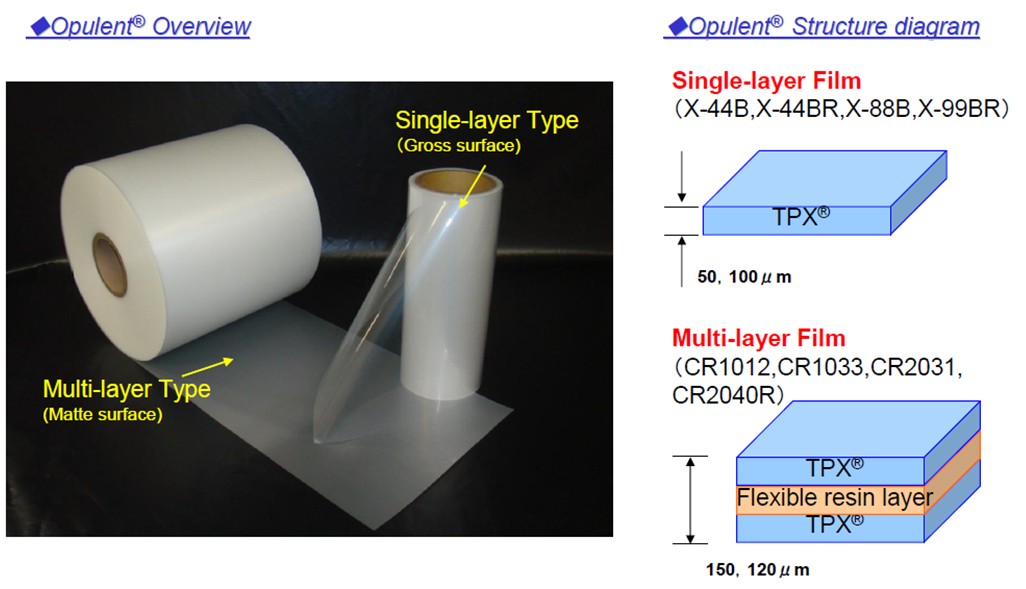

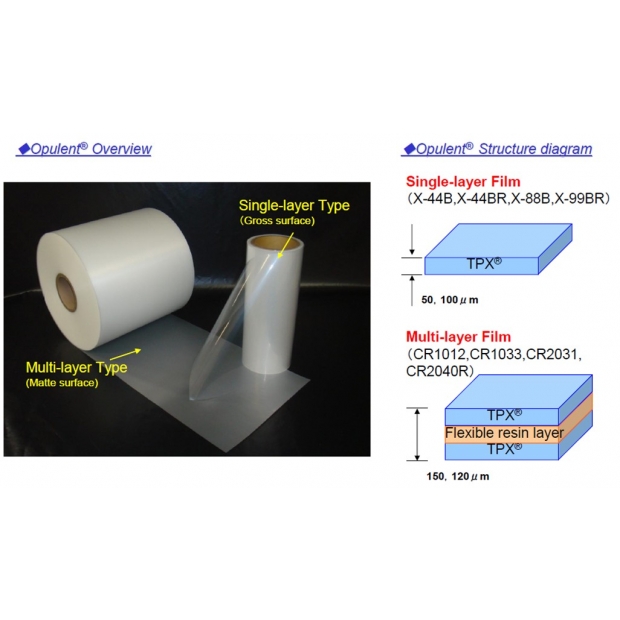

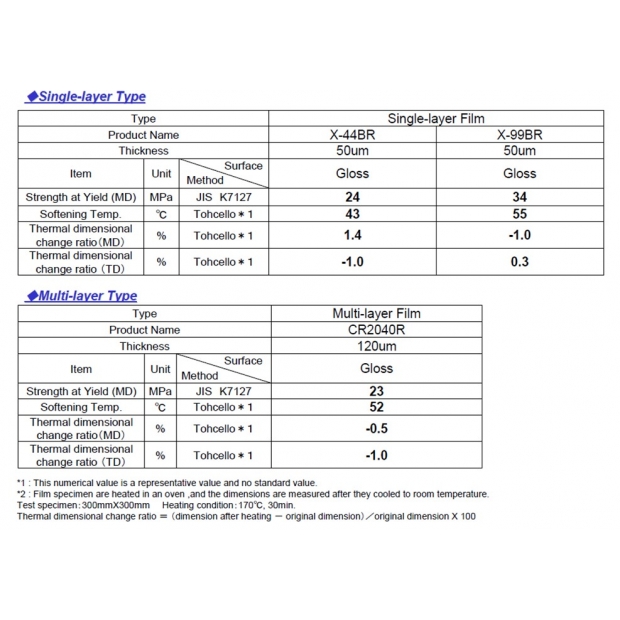

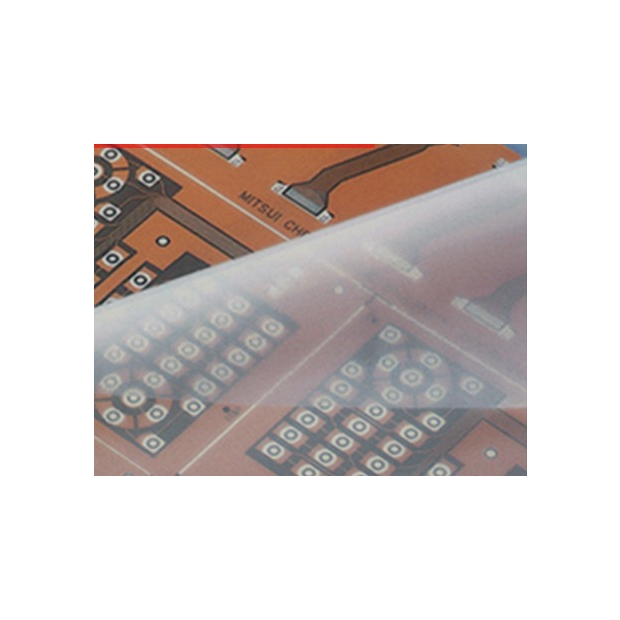

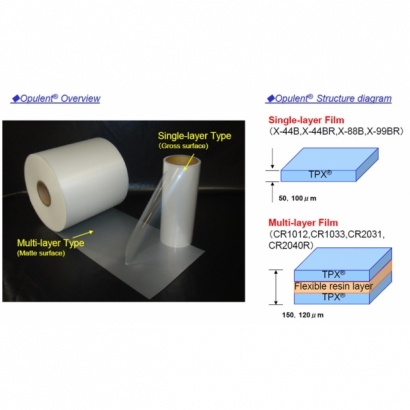

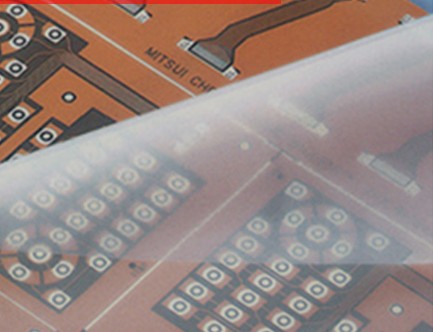

TPX™ (Polymethyl Pentene)壓合離型膜/ TPX™ (Polymethyl Pentene) Lamination Release Film

Main features: heat resistance, releasability

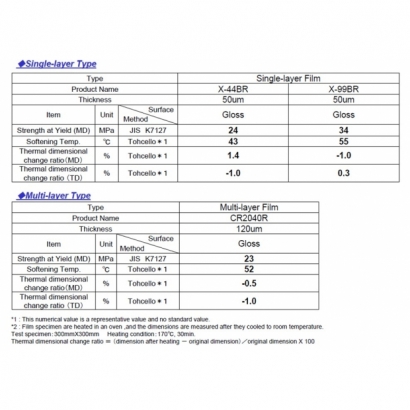

Properties:

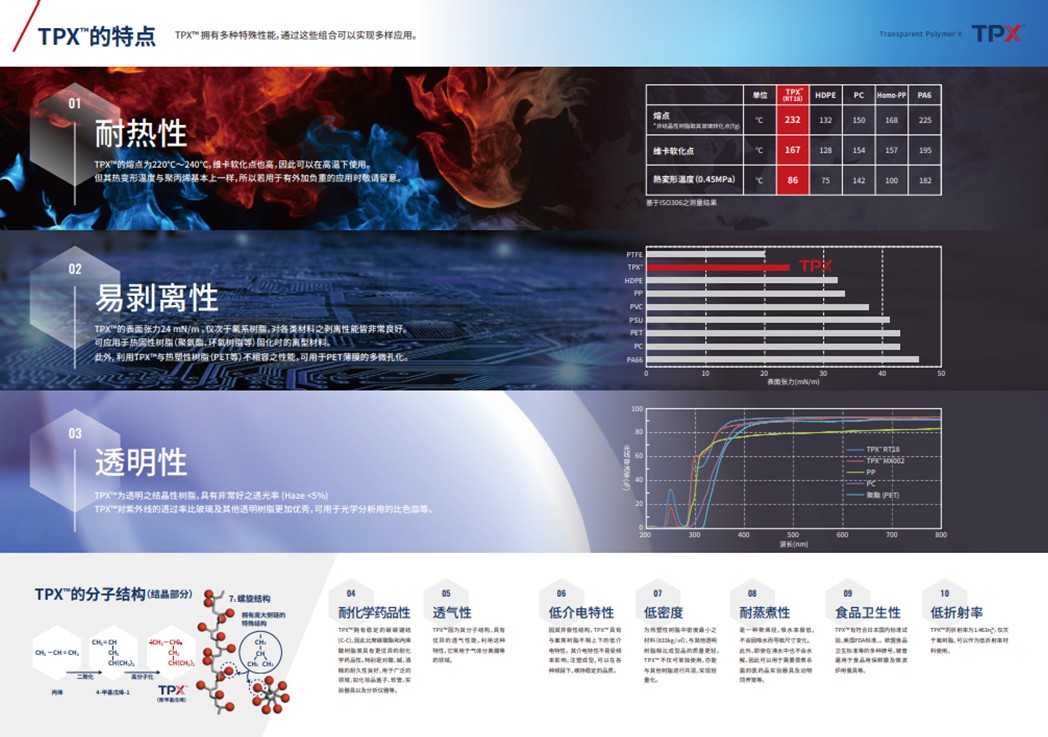

- Heat resistance: Melting point is 220~240 ℃, it can be used in high temperature environment.

- Release property: The surface tension is 24mN/m, second only to PTFE, with good peelability, non-sticking, and anti-staining.

- Transparency: Haze<5%, with the same transparency as glass and acrylic.

- Low dielectric coefficient: ε = 2.1, suitable for high frequency applications and electrical insulation.

- Lightweight: The density is 833kg/m3, which can achieve the effect of lightweight products.

- Chemical resistance: Good resistance to acid, alkali, alcohol, etc.

- Food hygiene: TPXTM is an olefin resin and does not contain harmful substances such as plasticizer BPA. And it complies with the US FDA, Japan Poly Health Association, China National Standard and other certifications.

- Low water absorption, steam resistance: water absorption <0.01%, good steam resistance, can be reused after disinfection. No need to pre-dry, no shape change due to water absorption.

- Gas permeability: TPXTM has numerous side chains with loose structure and low molecular packing density, so it has good gas permeability.